The Die Casting Mold

Die casting is a manufacturing process that allows manufactures to produce parts with three-dimensional shapes efficiently. The process involves injecting molten metal into die cavities at high pressure using a die casting machine. The molten zinc quickly cools and solidifies, taking on the exact shape of the die cavity. Then the die is opened and the newly formed part can be extracted, finished, and shipped.

The most important aspect of producing a great part is getting the mold right. The mold, also referred to as the die, is the block of steel that contains the empty cavity where the liquid zinc will take shape. The mold or die is usually the most expensive part of any new zinc die casting job. This is partly due to the cost of the hardened steel, but also due to the many hours of extremely precise work that must be done to cut away the steel to form the cavity to make the part.

It is essential to get the mold built correctly. The die casting process requires precise die casting tools to create parts that meet strict standards. Castings are frequently complex shapes, with very specific tolerance requirements. If the mold is wrong, no equipment or process improvements can overcome this problem. If there is a problem with the mold, it is feasible to remove additional material, but adding back material almost certainly reduces the tool life by a significant amount.

At Deco Products, our engineers use mold-flow simulation to help validate the part and mold design. This approach is critical for complex parts or parts with high surface finish requirements to maximize the success of the project, accelerate speed to market, and maximize the lifespan of the tool.

Die Casting Molds and Flow Simulation

Our customers develop innovate product designs. Our job is to help them realize these designs as manufacturable product. Frequently, this requires some modification to the existing design to ensure the part can be produced consistently and economically.

It is difficult to design a mold properly because molten zinc flows fast through the die cavity. There may be many problems as the molten zinc fills the cavity: sometimes there are issues when the zinc runs into walls and cores while cooling at different rates; trapped air could cause defects depending on where it is trapped or how much air is trapped; some areas of the cavity may not properly fill out all the way; some features may not be able to hold their shape as the mold opens.

In some cases, our Engineers need to innovate creative ways to design the molds to ensure we can predictably and successfully fill the cavity to meet all of the finish requirements and specifications. In difficult cases, mold flow simulation is a key tool. Mold flow simulation allows our Engineers to visualize how the metal will flow inside the cavity as it transitions from molten metal to a solid metal .This is an essential tool as the physics of each shot is too complex to predict by hand.

The Benefits of Mold Flow Simulation

Mold flow simulation delivers real advantages. Engineers find problems before building die cast dies, saving both time and cost. This happens well before mold fabrication begins to ensure the tool design has been thoroughly vetted. We can then proceed with higher confidence in the design of the mold given the customer requirements.

In some cases, mold-flow can accelerate the new product lifecycle by solving problems at the design phase rather than trouble shooting once the tool has been produced.

A good simulation also helps our Engineers channel molten zinc into the cavity evenly, allowing for higher quality and performance of the final die cast parts.

How Mold Flow Works

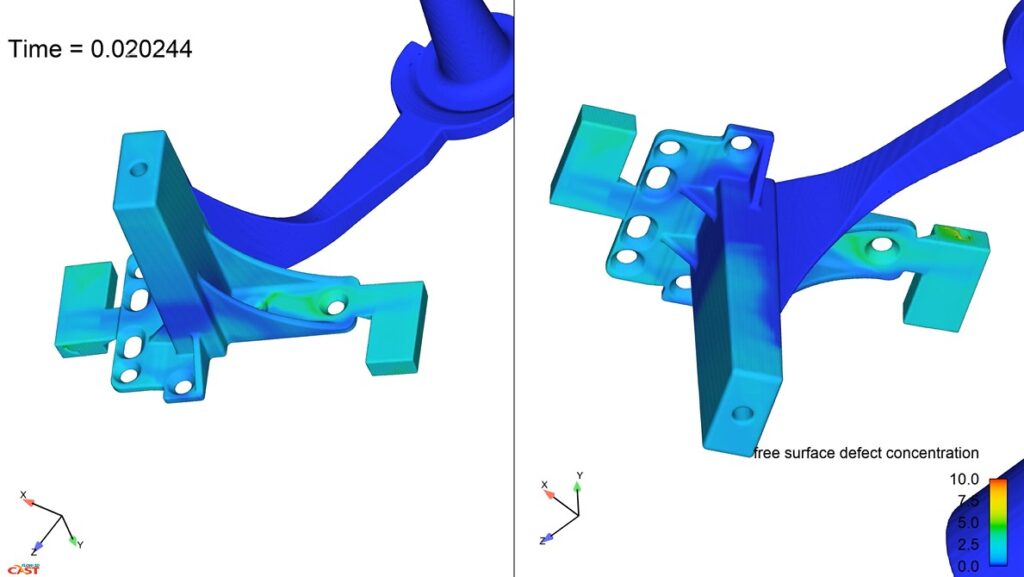

Here is an interesting example of mold-flow simulation.

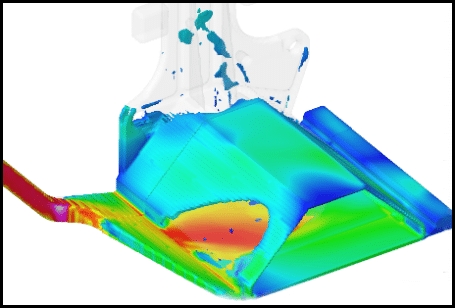

Our mold-flow software allows our design engineers to simulate the entire casting process by calculating the path of the molten metal as tiny particles flowing together through a 3d model of the cavity.

Our engineers are able to tweak parameters and mold design to iteratively analyze flow patterns in detail. The mold flow software helps the engineers monitor the velocity, temperature, and pressure of the molten zinc as it flows into the cavity and solidifies. They can also monitor how the interaction between the molten zinc and the entrapped air interact as mold design changes.

The team runs many tests during tool design. They try different wall thicknesses, gates, and flow rates. Each test gives data to improve the final design. You can read more about gates here.

Mold Flow and Mold Selection

Mold flow can be a helpful way to validate you’ve selected the right mold type. While the basic aspects of the metal casting process remain true regardless of whether you have a die with one cavity, multiple cavities of the same part, or multiple cavities of different parts, the flow of metal can be radically different.

Single Cavity Mold: Parts that are sensitive to porosity location, fill density, or surface quality requirements may be best in a single-cavity die.

Multi-Cavity Mold: However, if we can successfully put more than one cavity in a die while still filling the part correctly and symmetrically, we can lower the overall cost of production. For some simple parts, it can be easy to fit many castings in a mold, provided the flow of metal into the mold can be done at a high enough pressure and distributed symmetrically to fill out all of the cavities.

Family Mold: In some cases, customers want to use a “family mold”, where two or more different parts are produced at the same time. This can be a useful technique when two parts are used together for the same final application. However, family molds can also lead to long term frustration if inventory needs to be rebalanced or if one cavity wears out before the other. Mold flow can be an important way to ensure a family mold is properly designed to keep the flow of metal symmetrical and minimize defects or entrapped air.

Conclusion

The Deco Products Engineering Team has over 400 years of combined experience. They pair this knowledge with advanced simulation technology to create optimized die casting tools from the start.

Deco works with customers during the design phase to help solve potential problems from the start. Our Engineers spot potential issues early and suggest changes that improve quality and reduce cost.

Frequently Asked Questions

How does mold flow simulation improve die casting mold design and efficiency?

Mold flow simulation is essential for designing efficient die casting tools. Engineers simulate molten zinc flow through the die cavity. This reveals issues like air traps, incomplete filling, and temperature problems.

The simulation process allows many design iterations to optimize gate placement, runner design, and vent locations. They ensure even filling and proper solidification of the cast material.

Flow3D-Cast software helps engineers find and fix issues during the design stage. This proactive approach eliminates costly trial and error. It improves overall mold performance and part quality.

What are the different types of die casting molds, and how do they affect production?

Although there are several types of molds, there are three molds we commonly work with in our conventional machines.

Single-cavity molds make one metal part per cycle. They work well for moderate volumes and complex designs.

Multi-cavity molds make multiple identical parts at the same time. This type significantly boosts production efficiency. It reduces per-part costs for high-volume manufacturing.

Family molds make multiple parts in one cycle. This ensures balanced inventories of components used together. These die cast dies often include sliding mechanisms or cores for complex features.

Mold type selection impacts die casting tools’ costs and production output. Multi-cavity and family molds cost more initially. However, they offer superior output rates and cost savings for large production runs in the die casting process.