When it comes to prototype zinc die castings, there is no perfect solution at this time. The following list provides some typical options for prototyping zinc die castings and each has some advantages and disadvantages. Please contact a Deco Product expert to help navigate these options for prototyping and further support during the design verification/validation processes.

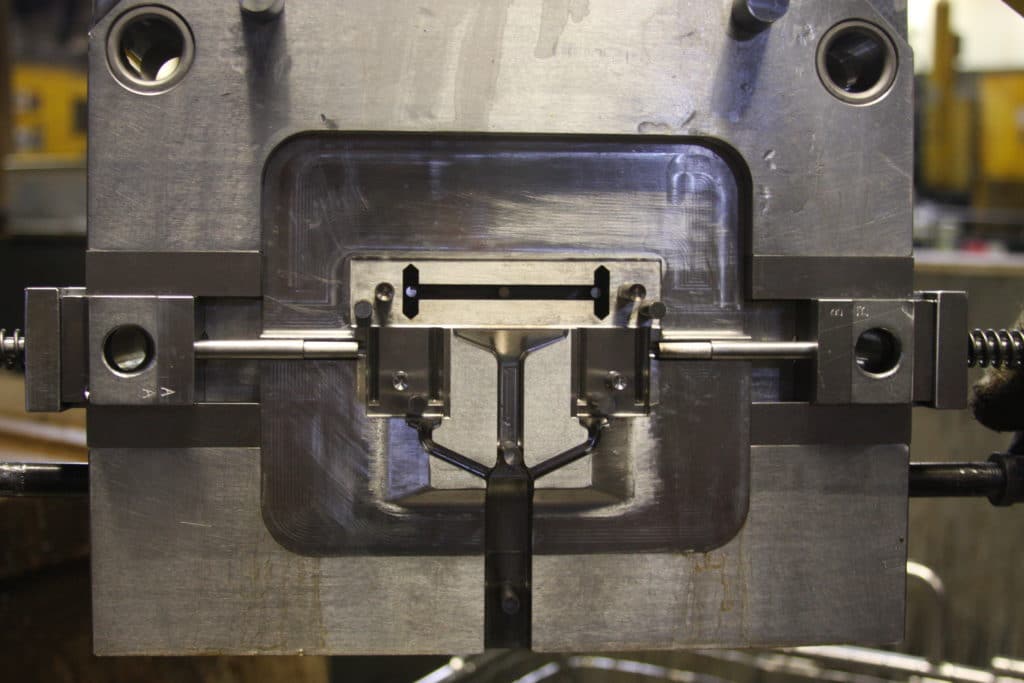

The best way to simulate the production process is to actually tool up the parts of the new design in a low cost and quick way. Deco can work with you on the best strategies to use actual tool steel and production machines early in the development process. This is often the best solution to get actual production representative parts quick and at a low cost. There is some “upfront cost”, but cavitation can be limited and resulting piece price for higher quantities is lower.

This approach produces production representative parts with similar material, geometry and strength. So as a designer, you can get the best results quickly during the critical design/testing phase. Additionally, this option can provide a “bridge” to initial production.

This prototyping approach machines parts out of zinc blocks and provides for quick prototypes. They can be of same alloy but are often expensive per part. Unfortunately, the surface characteristics of the part are compromised as the material is machined so production representative high-pressure surface “skin” is not provided.

Prototype tooling is less expensive than production tooling with this method, but more expensive than other prototyping methods. Complex geometries are possible, but the quality is compromised and the quantity of parts to be produced is lowered. This method is expensive but can provide a better surface finish than other prototyping methods.

These prototypes can be provided in a variety of alloys and with low tooling cost, but each part is expensive. This method is best suited for smaller parts and although complex geometries can be achieved often tight tolerance features may have to be machined with a secondary operation.

Has a low up-front cost, but each part is expensive. The size of the part can be bigger, but the surface quality is compromised. The lead-time for parts is short, but the “as-cast” feature precision is often undesirable---often leading to machining areas that need tighter tolerance.

3D printing has evolved and redefined many industries, but with this said, currently production die cast representative parts cannot be made. This technology does provide an excellent method to prove fit and acceptance of various geometries. This method can be used to examine many design iterations quickly and at a low cost.

No spam! Just relevant news, events, and updates about Zinc, Deco, and our services. Sign up for our quarterly newsletter today!

Deco Products is a full-service zinc die-caster that offers precision zinc die-castings to customers globally. We utilize custom-designed hot-chambered die-casting machines to offer you competitive and quality products.