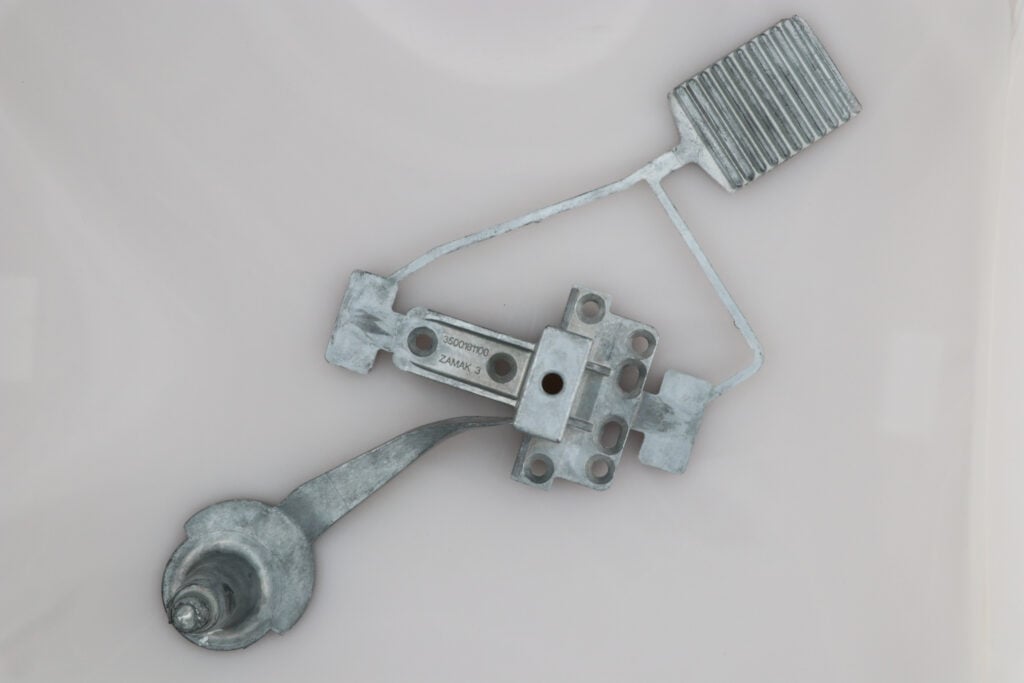

You are looking for lightweight, high-quality parts with high strength and tight tolerances, without breaking the budget. High-pressure zinc die-casting delivers all three.

At Deco Products, we are experts in working with hot chamber die casting. Our experience and knowledge in this manufacturing process have consistently solved real design challenges for engineers across multiple industries. Through our experience, we think zinc is among the best raw materials to work with in the die-casting business.

How High-Pressure Die Casting Works

The high-pressure die casting production process is similar across all alloys. A cavity is machined out of blocks of steel, leaving an empty shape that forms the manufactured part. This steel die has two halves, so the die can be opened and closed.

Once the tool has been produced and placed in a die casting machine, the metal alloy is melted to a liquid state for the die casting process. The die-casting machine closes the two halves of the tool. Then uses a plunger to force liquid metal into the cavity at extremely high speed. The liquid metal flows into the cavity and quickly cools, starting at the surface and working its way in.

In a few seconds, the part cools enough to solidify. Once the part solidifies, the die opens and the part ejects. This rapid cycle time allows us to produce thousands of identical parts.

Why Zinc Works Well

Many manufacturing metals are thick and viscous when melted to a liquid. When manufacturers use these metals for casting, they flow more slowly and struggle to fill complex features or thin walls. When zinc melts, it is fluid; it flows more like water.

This water-like flow allows zinc alloys to fill complex shapes: the liquid zinc flows into thin walls and tight corners that other metals cannot reach. For zinc castings, wall thicknesses can go as thin as 0.2 millimeters.

That creates lightweight parts without sacrificing strength. This water-like flow also provides casting features with tighter tolerances. As such, zinc castings can be designed with features that would normally require secondary operations or machining. This allows customers to design castings that are cast into the finished product.

Zinc also melts at a much lower temperature than other manufacturing metals. These lower temperatures make zinc much less abrasive on the steel tool as the hot zinc flows across the steel surface. As such, zinc casting tools can have a much longer lifespan than the tools of other castings metals.

In many cases, we’ve seen zinc tools last well over 1 million shots. However, like all casting tools, tool life is also strongly influenced by geometry. Simple parts may last longer, while complex shapes may wear out faster. Regardless, we expect the steel tools used for zinc to last around 5-10x longer than other casting metals due to the combination of low temperature and high fluidity.

The lower melting point also means zinc has fast cycle times and increased productivity. This high production efficiency keeps your total cost low, especially compared to other manufacturing methods. The lower melting point also supports reduced energy cost. This allows zinc die-casting to use less costly energy and significantly reduces the environmental impact compared to other casting methods.

Zinc is also naturally corrosion resistant and does not rust. Instead, zinc reacts with oxygen to form a natural patina, protecting it from further corrosion.

Zinc is also highly recyclable, which helps reduce total waste and cost. Overflow from the zinc castings and rejected material can be remelted and reused right away. This re-use efficiency makes zinc extremely efficient and sustainable to use, and keeps the cost of production low.

Designing Lightweight Parts

When working with zinc, you have an opportunity to reduce weight by designing thinner walls than other castings can handle, while still supporting excellent impact and structural strength. Taking advantage of the ability to produce thin walls is essential for optimizing part weight, as zinc has a much higher density than aluminum alloys.

Being thin does not mean being weak: you can incorporate ribs into your design for added strength. Ribs improve the flow of molten metal through the die. They also increase the strength and rigidity of the finished part. Zinc die casting lets Engineers develop parts that have incredible strength, are lightweight, have a low piece price, and long-lasting tools.

Design Support From Our Team

Successful die casting starts with good part design. Our engineering team provides Design For Manufacturability (DFM) consultation. We review your designs early to spot potential casting challenges.

Draft angles, wall thickness, and feature placement are all critical to consider as we work to optimize your product performance at the best total cost. Our team will identify any potential concerns to help you minimize production costs and maximize product stability and tooling lifespan.

Gate and runner design significantly affects part quality. Good gating ensures the mold fills completely without trapped air. Proper overflow placement prevents porosity. Our experience guides you to optimal tooling design.

We use Flow-3D simulation software to test designs before tooling fabrication. These simulations show metal flow patterns. We can predict how the zinc will flow through your die and identify potential problems early. We can adjust your design and the gates and runners that flow the metal into your part to reduce your risk of problems down the road.

The simulation also helps us design tools for a longer tool life. We can see where zinc buildup might occur and which features have the highest risk of erosion because of the high-pressure molten metal.

Converting Aluminum Parts to Zinc

Manufacturers can effectively replace many aluminum die casting parts with zinc die casting parts. This conversion can lead to cost savings and better performance. Zinc has a lower casting cost than aluminum, thanks to the superior cycle time, lower melting point, and ability to consolidate operations into the design of the casting. Its superior flow also allows for more intricate details than aluminum can produce.

Our engineers specialize in design for manufacturability and review each RFQ. We can review your part and let you know whether or not it is an excellent candidate for zinc. Once you select zinc as your material, we can work with you to optimize your design for manufacturability while meeting your performance needs.

For more insights into zinc die casting, listen to Dave Magner, our Director of Sales and Marketing, on the Small Business Talks Podcast. Dave explains how zinc die casting solves real manufacturing challenges, and when zinc is the right material.

Starting Your Next Project with Deco

The best time to consider if you want to convert a part to zinc is before your current tool has worn out. As your tool begins to wear, reach out to us to consider if the product can tolerate a design change to optimize your cost and functionality with a zinc casting.

Our team can take a quick look at your design and let you know if they think it will be a good fit. Then, the Deco team will assess the machine, alloys, and operations needed to make your product.

Feel free to reach out anytime to discuss your next project. Visit our About Us page to learn more about our capabilities.

About Deco

Deco Products is one of North America’s largest stand-alone zinc die casting manufacturer. We have served customers since 1960. Our facility has over 100 die casting machines. They range from 14-ton to 500-ton clamping force. We offer both conventional and multi-slide die casting to support a wide-range of product complexity and make sure your products run in the most cost-effective machine.

In addition to die-casting, we offer a full suite of secondary operations to keep as much of the manufacturing process under one roof, including powder-coating, conventional and cnc machining, and assembly. In addition we also subcontract plating services for customers who need functional or decorative plating processes applied to the zinc. By having Deco subcontract for you, it allows us to proactively manage the casting and plating quality for you.

Deco is a proud supporter of Made in USA supply-chain. The vast majority of our key supply chain is only a few-hours drive away from our facility, giving us an excellent ability to respond to unexpected needs quickly.