Deco Products specializes in zinc die cast manufacturing offering a range of services. Since 1972, Deco Products has had zinc powder coating capabilities in house. By offering powder coating directly, Deco is able to reduce lead-times, better manage quality, and offer customers better total cost.

Overview of Powder Coating Process

Powder coat is a dry powder typically applied electrostatically and cured under heat or with ultraviolet light. The result is a hard finish that is stronger and more reliable than conventional paint applications. Zinc die cast alloys provide an outstanding base or substrate for a clean, aesthetic, and durable finish.

Electrostatic Application

Powder coating involves an electrostatic application that utilities the charged particles or powder to coat a zinc part. These powders can be applied with either a manual process or a fully automated process. Given the volumes of products processed at Deco, the powder application process is automated to maximize consistent coverage.

A key advantage is that the powder wraps well to normally shielded surfaces thanks to the statically charged powder. This allows coverage to reach normally difficult to paint areas. The powder coat process also makes it relatively easy to mask holes or features which should not be painted.

Durability

The powder coating application adheres extremely well to a die cast part, resulting in a resilient and robust finish. This helps the product withstand chipping and scratching, allowing powder coated parts to last longer and require less maintenance, even in tough conditions. Powders can also be specially formulated to improve resistance to color fade, especially for outdoor applications.

Customize Options

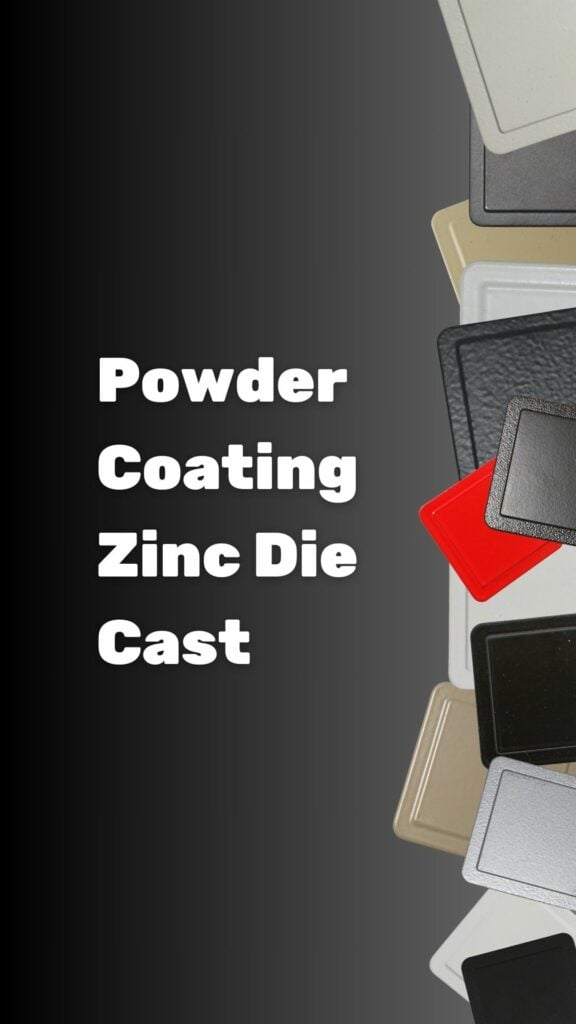

The most economical choice for powder coating would be to use a common off-the-shelf option. Deco Products offers a wide variety of colors and finishes. However, customers with specific needs can also work with Deco to develop a custom color to match their specific application needs. These powders tend to be significantly more expensive compared to standard options but enables customers to tailor solutions to commercial needs.

The sales team can aid the process of choosing a color. Visit our preferred zinc powder coats and contact us to request a sample paint chip

How Does Powder Coating Compare to Liquid Painting

While both are popular powder coating and liquid paint have different finishing processes. Deco’s powder coating capabilities allow for benefits compared to liquid painting.

Cost Savings

Powder coating tends to be more cost-effective because of its ability to reduce maintenance and replacement costs. Additionally, the overall process efficiency in the powder coating process can lead to lower production costs, as it typically requires less material and labor compared to liquid paint.

Cleaner Environmentally Friendly Processes

Compared with traditional liquid painting methods the powder coating process is cleaner. Powder coating capabilities reduce overspray and emission of volatile organic compounds (VOCs), which contributes to environmental and workplace safety benefits. The use of a powder application also reduces the use of strong solvents typically present in a liquid paint process.

Better-Quality Finishes

The use of a powder coat also supports a more consistent finish quality than liquid paint. By applying a powder coat and then melting and curing that paint on the part, the painted finish tends to produce a smooth, uniform, and drip-free finish.

Powder Coating Capabilities Potential Disadvantage

Although powder coating offers many advantages to liquid paint, there are a few important issues to consider when evaluating a paint application for your needs.

Variation in Thickness

Powder coating can have variation in the thickness applied to a part. This can be influenced by a variety of factors, including the part geometry, the electrostatic characteristics of the powder, and the effectiveness of the powder reclaim process.

It is important to consider where specific tolerances must be maintained when evaluating painting options. In many cases, there are specific mitigation strategies that can be used on key tolerances, such as masking or post-painting machining. Our Engineering team can also help you evaluate potential overlapping tolerance concerns if the products need to function in an assembly.

Finish Appearance

Certain types of powders may have idiosyncratic defect issues due to the color or performance of additives present in the powder recipe. Alternative options, like liquid paint or plating, may ultimately be preferential in cases where powder coating formulation is limited.

Ultimately, the choice between powder coating and liquid painting depends on the specific requirements of the project. Both methods have their place and understanding their differences is key to selecting the appropriate finish.

Conclusion

Deco Products has over 50 years of experience with powder coating zinc castings. Our powder coating capabilities help provide our customers with great color options and finish quality while helping our customers manage total cost. Visit our capabilities and services page to learn more.

Powder Coating Capabilities Frequently Asked Questions

What is the curing temperature used in the powder coating process?

The curing temperature for powder coating typically ranges between 350°F (177°C) and 400°F (204°C). This temperature range ensures that the powder coating properly melts, flows, and forms a durable, hard finish on zinc parts.

What are the steps in the powder coating process?

1. Wash: The zinc parts are cleaned to remove any dirt, grease, or contaminants.

2. Dry: the washed parts go through a dry-off oven to ensure the clean surface is dry and ready for powder application

3. Powder Application: Powder is fluidized using air and electrostatically applied to the zinc parts using automated applicators. The charged powder particles wrap around the part and adhere to the part.

4. Curing: The parts are run through an oven to heat the finish. The heat causes the powder to melt, allowing the powder to flow. This melted powder flow forms a continuous durable film. The parts remain in the oven for a specified time to cure the finish.

5. Cooling: After curing, the parts are cooled to room temperature, allowing the coating to harden and set.

Do powders create harmful chemicals?

Historically, some legacy powders previously contained chemicals of concern, such as PFAS (Per- and Polyfluoroalkyl Substances). However, the industry is rapidly removing these substances from their formulations. Most of Deco’s standard recommended powders are now completely PFAS-free, but feel free to reach out to us for special confirmation.

Many powder coating companies have also updated their product formulations to comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) standards. This ensures that the powders are safe and environmentally friendly in their cured formulation.

It is important to confirm the compliance of the powders being used, especially when working with legacy powders that may not meet current standards.

What is the difference between off-the-shelf and custom-match powder coatings?

Off-the-shelf powder coatings are standard, pre-formulated colors and finishes that are readily available, cost-effective, and quickly delivered but have limited selection.

Custom-match powder coatings are specifically formulated to meet unique color and finish requirements, offering greater flexibility and precise color matching, but they typically have longer lead times and higher costs due to specialized formulation.

What is the difference between reclaim and spray-to-waste in powder coating?

Reclaim powder coating recovers and reuses overspray, reducing material waste and cost. This process is inherently more environmentally friendly by reducing the potential waste of overspray (powder that does not end up adhering to the part).

Spray-to-waste powder coating does not reclaim overspray, leading to higher material usage and waste. This is a simpler process and less capital intensive but has a higher variable cost due to the lost material. Spray-to-waste is often the process used when using extremely low volume powder that does not economically justify investments to support the reclaim infrastructure or changeover of that reclaim infrastructure.

Capabilities & Services

Michele Duwe

Michele Duwe is the Sales and Marketing Manager with Deco Products. She has eight plus years as a digital marketing manager and over a decade of sales and marketing experience.