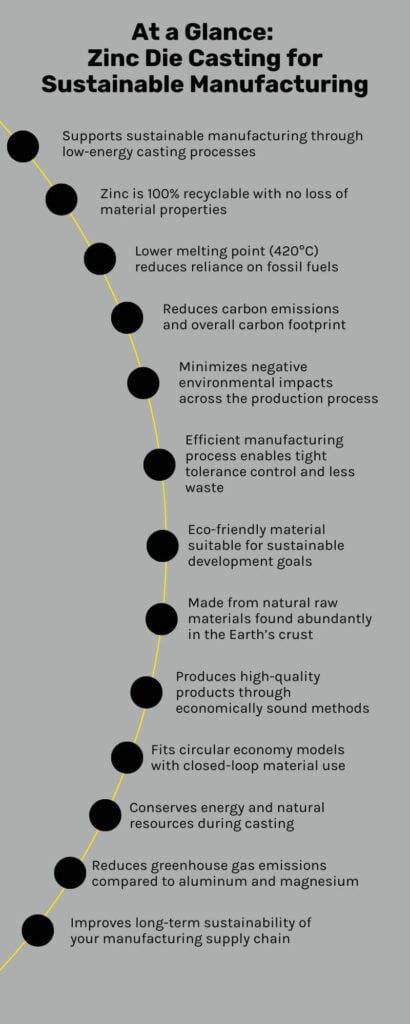

Deco Products is committed to minimizing negative environmental impacts through responsible zinc die casting and sustainable manufacturing. We aim to reduce waste, save energy, and protect natural resources. We also use methods that limit harm to the environment.

Zinc die casting supports these goals by delivering energy efficiency and long-term performance. In recent years, zinc has gained attention as a safe, recyclable, and eco-friendly material. Its use in manufacturing helps companies meet sustainable development goals while producing durable, high-quality components.

Zinc is one of Earth’s most abundant raw materials, found naturally in the planet’s crust.

Commonly found in everyday items such as doorknobs, window latches, medical tools, and other essential products. Zinc is a good choice for companies that want to lower their carbon footprint. It has low toxicity and recycles easily, while still keeping product performance high.

Zinc alloys support eco-friendly production by offering extended tool life and high casting precision. Unlike other metals, you can recycle indefinitely without degrading. With its properties, you can recycle zinc even when a product reaches the end of its life cycle. Reducing waste across the supply chain.

Zinc alloys are one of the most energy-efficient materials used in the die casting production process. With a low melting point of approximately 420°C (787°F) zinc requires significantly less energy to process. When comparing the manufacturing process to other metals like aluminum (660°C) and magnesium (650°C). This lower energy demand translates into fewer fossil fuels consumed during manufacturing.

Lower energy use also reduces greenhouse gas emissions, supporting long-term sustainability goals. Zinc casting requires up to 35% less heat than aluminum. Helping manufacturers decrease their overall carbon emissions and meet regulatory standards.

In addition, faster shot cycles and shorter solidification times lead to reduced processing time. This efficiency supports sound processes that minimize environmental impacts while conserving energy and natural resources.

Zinc alloys play an important role in achieving sustainable manufacturing. At Deco Products, our manufacturing process prioritizes precision and efficiency.

These attributes enable us to produce high-quality parts while using less energy and fewer resources. Zinc casting produces products through economically sound and resource-efficient methods that align with environmental goals.

As one of Earth’s most sustainable metals, zinc helps manufacturers maintain quality standards while minimizing environmental risk. Its compatibility with renewable energy sources and recycling infrastructure makes it a smart choice for companies looking to reduce their long-term environmental impact.

At Deco Products, we leverage zinc’s natural properties and design flexibility to reduce the impact of industrial production. Our operation teams use processes that minimize negative effects on the environment while delivering durable, high-performance components.

We believe in producing eco-friendly solutions that are both cost-effective and environmentally responsible. Whether your goal is to reduce waste, lower your carbon footprint, or improve efficiency in your production process, zinc can help you get there.

Zinc supports responsible and sustainable manufacturing by combining low energy use, recyclability, and design efficiency. At Deco Products, we are proud to manufacture zinc parts that align with today’s sustainability standards and tomorrow’s environmental goals.

Choosing zinc is a practical step toward reducing environmental impact—without compromising performance or quality.