Deco Products has been a prominent player in the zinc die casting industry since 1960. We attribute our success in this industry to our systems, equipment, and operational and engineering expertise. Which allows us to undertake stress-free and expedited zinc die cast tooling transfer projects.

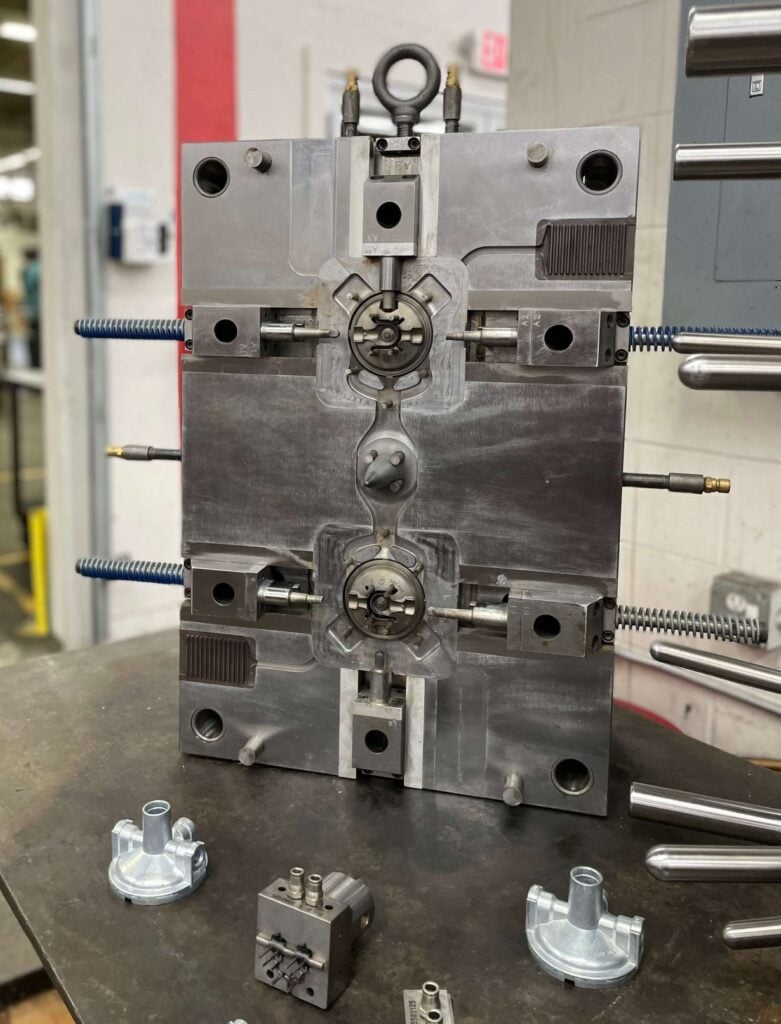

The tooling transfer process at Deco Products is simple yet effective. First, our engineering team will review the part, other specifications and requirements for the tool design. We will ask questions and gather information on the tool transfer before delivery of the tool. Upon delivery we will review the tool, evaluate the condition and determine any adaptations necessary.

Our team has decades of experience in tooling transfer projects. Which allows us to quickly identify any potential issues and develop an appropriate plan to address them.

Next, Deco will determine the best fit for die cast production of our many zinc die casting machines.

With over 100 die cast machines, we are likely well positioned to have the proper equipment to fit and run the existing mold.

Ensuring a seamless and efficient transfer process. Our on-site tool room easily takes care of modification to meet production requirements. Utilizing an on-site tool room saves our customers time and money.

Tooling can then be sampled in an efficient and production representative way. With our many machines, we have the capacity to quickly sample the tooling without interrupting other scheduled production jobs. Next, our on-site QA lab ensures sample parts meet the customer requirements and Deco’s high-quality standards.

At Deco Products, we understand that every tooling transfer project is unique. However, with our decades of experience and expertise, we can adapt to specific requirements for your transferred tooling. Our team of experts is committed to providing stress-free and efficient tooling transfer projects to our customers.

Deco Products has been a leader in the zinc die casting industry for over six decades. Thanks to our expertise in tooling transfer projects and new part designs. Our conservative practices and debt-free status have ensured stability for our customers even during challenging economic times. At Deco, we have the systems, equipment, and engineering experts to ensure stress-free and expedited tooling transfer projects.

Here is our tooling transfer project checklist that we follow to ensure successful project completion:

We start by understanding the project parameters. Such as schedule and cost to ensure that we meet our customer’s expectations.

We review the tools to be transferred by sharing various types of information such as tooling drawings, tool photos, number of cavities, and on-site audits.

When the tools arrive, we size the fit of the tools to one of our over 100 zinc die casting machines and existing tooling holders or fixtures for adaptation.

If needed, tooling can be modified or adapted with new componentry in our on-site tool room.

We can sample the tooling in an expedited but production representative way. With our many machines, we have the capacity to quickly sample the tooling without interruption of other scheduled production jobs.

We have an on-site QA lab to conduct 1st article inspections and layouts as part of the production part approval process (PPAPs).

Samples are sent to the customer for review and approval.

It’s important to note that every tooling transfer project has its own unique set of circumstances. Our decades of experience and engineering expertise, uniquely positioned to adapt to specific requirements and capabilities for your transferred tooling. Our experts are problem solvers and can provide a smooth and stress-free process for our customers.

At Deco Products, we take pride in providing our customers with the highest level of service and support. We are committed to meeting their needs and exceeding their expectations.

Deco Products is a full-service zinc die-caster that offers precision zinc die-castings to customers globally. We utilize custom-designed hot-chambered die-casting machines to offer you competitive and quality products.