Die casting tool design and management is a key component in your project success. At Deco Products, our skilled engineering team collaborates with customers. We optimize your tool design for quality and lower product costs.

Since 1960 we have been designing and maintaining zinc die cast tooling in the United States. Our experience has taught us the best practices for die design and management. We’ve also learned how to get the most out of our dies and optimize their longevity.

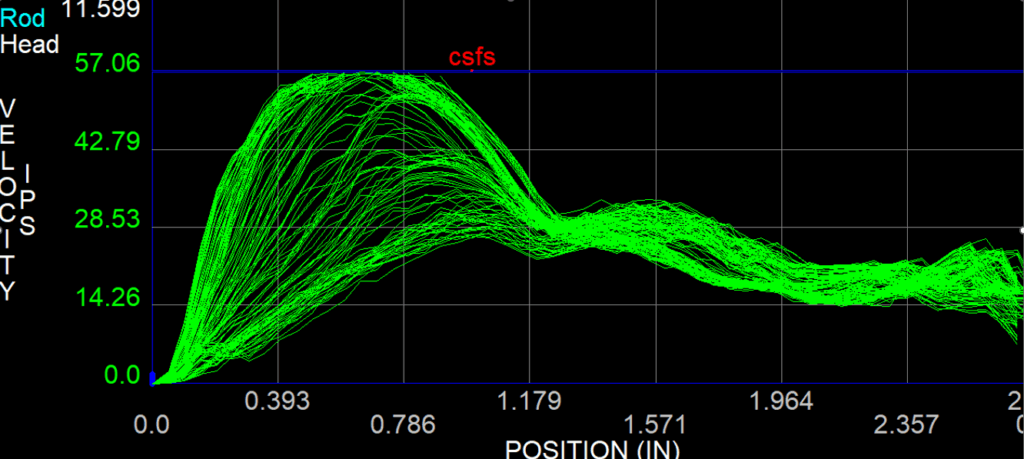

We use Flow-3D Cast simulation software which allows us to analyze the mold flow and tool design. This software is critical in creating superior products.

Achieving optimal results in zinc die casting heavily relies on designing and fabricating the right tooling. From mold design to die production, each aspect plays a vital role in the success of the tooling implementation. At Deco, our experienced engineers work closely with customers to ensure the optimal design of die casting tooling. This is just another way Deco Products supports our customers for the best long-term value of the product life cycle.

Our commitment to excellence has made us a supplier of zinc die castings to customers all over the world.

Firstly, with over 60 years of experience, we have the ability to help with your part design and produce the most challenging components. Secondly, Deco has the production capabilities to ensure we can support a broad range of physical requirements.

Deco can tool intricate castings to run with tight tolerances in our wide variety of die-casting machines. This variety gives us the capacity to produce parts as small as several ounces to as large as 8 lbs.

We know precisely how to eliminate common defects like porosity, entrained air and blisters, and surface cold shuts. Therefore, you can count on the quality of the products you receive from Deco.

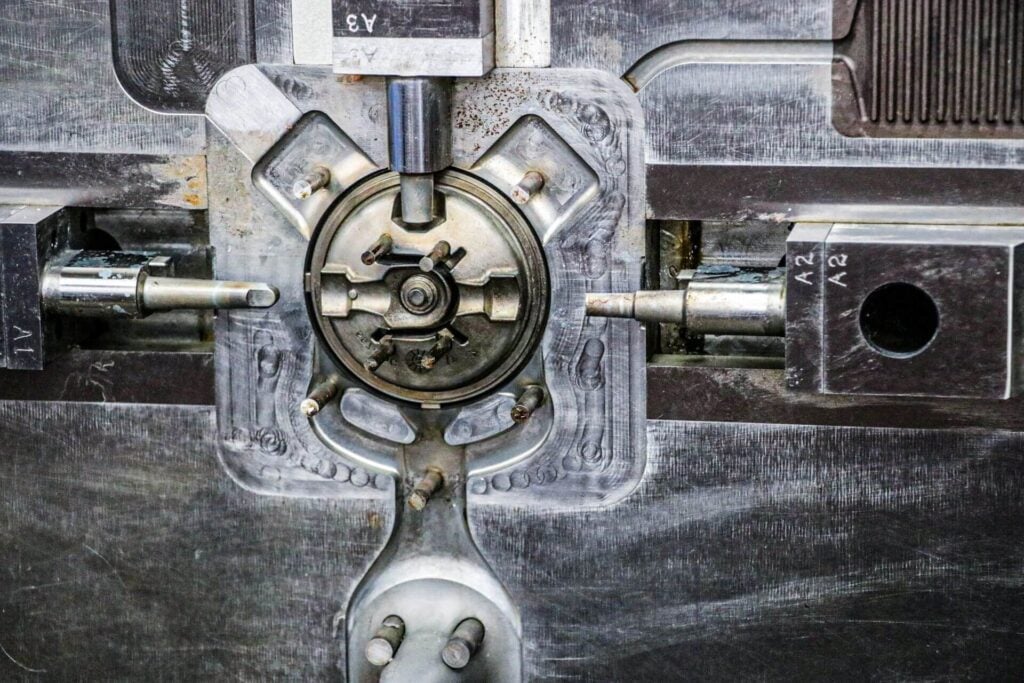

Success in the production process relies on two essential components: the cast die mold and the trim die. At Deco, we use premium heat-treated H-13 die steel, which ensures long tool life and a high return on the customer’s tooling.

Some of the most challenging simulations for accuracy revolve around metal casting applications. It all starts with a logical sequence that closely follows the sequential key processes. We take into account the complex range of the physics involved along with the challenges of thin-walled castings.

We focus on the simulation of our hot chamber method to discover and accurately predict filling and solidification. Then apply the best modeling workflows to allow us to meet your specifications.

Mold Flow Analysis software allows Deco Products engineers to optimize the design of molds.

By employing specialized software, our engineers can simulate the flow of molten zinc alloys within the mold. Gaining valuable insights into the casting process. This software allows us to evaluate factors such as fill time, flow velocity, and pressure distribution. Deco’s Engineers will adjust the design to achieve optimal outcomes.

The simulation provides a comprehensive understanding of how the molten zinc will behave during the casting process. Enabling the identification and mitigation of potential defects and surface finishes. By visualizing the flow patterns, hotspots, air entrapment, and areas prone to shrinkage or porosity. Our engineers can make informed design modifications to enhance mold performance and minimize defects.

Furthermore, mold flow analysis aids in optimizing gating systems and runner designs. Ensuring efficient filling of the mold cavity while reducing turbulence and material waste. By precisely controlling the filling process, manufacturers can achieve consistent part dimensions and minimize post-casting production costs.

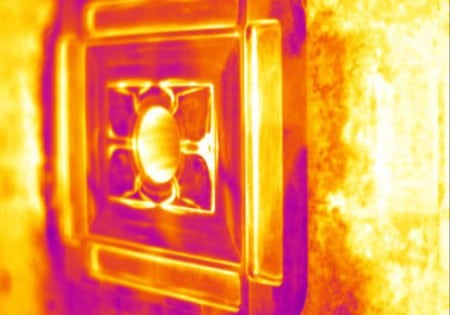

Maintaining precise control over thermal factors in die casting molds is crucial for consistently producing high-quality parts. However, achieving this control can be challenging because of variations in part design and production systems. By closely monitoring and analyzing temperatures within the mold. It allows the possibility to enhance part quality and extend the life of the tools.

To facilitate this process, thermal imaging cameras are invaluable tools that enable the monitoring of tool temperatures. The detection of thermal variations occurring within the die during tool usage.

At Deco Products, we take great pride in employing cutting-edge thermal imaging technology. These cameras enhance temperature monitoring and assist in maintaining optimal control over the manufacturing processes. Through the information provided by thermal imaging, we gain insights into both absolute and relative temperature data. Enabling us to identify areas with higher or lower heat distribution within the tools.

By utilizing this technology, we significantly improve the accuracy and comprehensiveness of the thermal profile of our tools. A critical factor in consistently casting high-production parts.

By incorporating thermal imaging, we achieve more consistent production runs and establish superior control over the die casting process. Resulting in improved part quality, reduced scrap, and prolonged tool life.

Furthermore, thermal imaging allows us to validate mold flow simulation analysis. As well as facilitate the development and control of die lubrication and spray throughout the die casting process.

The trim die plays a crucial role in the zinc die casting process. This tool removes excess material such as runners, overflows, and flash from the castings. We design it as a separate tool, either in a single or multiple cavity configuration. This tool mirrors the same design as the die casting die itself.

Once the molten zinc solidifies and we eject the casting from the die, the trim die comes into action. It precisely trims away any unwanted material surrounding the cast part, ensuring a clean and finished product. We carefully craft the trim die to match the intricate contours and features of the casting. Enabling precise trimming without damaging or altering the integrity of the final part.

By utilizing the same configuration as the casting die, the trim die ensures consistency and accuracy in the trimming process.

Our engineers assist the design to ensure the right tooling for producing high-quality zinc die cast parts. With the design of the right tools, you can unlock the full potential of zinc die casting and achieve outstanding results.

Deco carefully maintains your tools to optimize their production life. After every production run our dies are sent through ultrasonic cleaners to ensure our next production run begins as if the mold was new. This includes a two stage process that breaks down buildup from the last production run and a rinse that includes a rust inhibitor.

Our well-staffed tooling department maintains dies on each of the three shifts. We ensure excellent maintenance and supervision of these valuable resources to maintain minimal production interruption.

Deco Products is a full-service zinc die-caster that offers precision zinc die-castings to customers globally. We utilize custom-designed hot-chambered die-casting machines to offer you competitive and quality products.