Prototyping

There is no perfect way to prototype a zinc die casting without purchasing a tool and running a production cast sample in a genuine die cast machine. That said, there are several ways Deco can help you with your attempt to prove your casting needs. The strategies we use to assess casting feasibility depend upon what question the prototype needs to answer. There are usually 3 ways we can think about the prototyping concept.

All good product designs start with an engineering review. When you are designing a new part in zinc, it is okay if you don’t understand anything about the zinc diecasting process. We can support you every step of the way and walk you through the process step by step, from the initial print to the final product approval.

Reviewing the print is always the first and most important part of developing and testing any new zinc die cast product. Our Engineers can review the print and approximate both the physical performance and the production feasibility based on your current design.

This part of the process is critical at answering the question of whether or not the features that have been designed into the drawing can be produced as a casting or will require additional machining operations to achieve the product design. We can also identify other concerns with the product — for example, are there any concerns with thin walls or the mechanical properties for the product application.

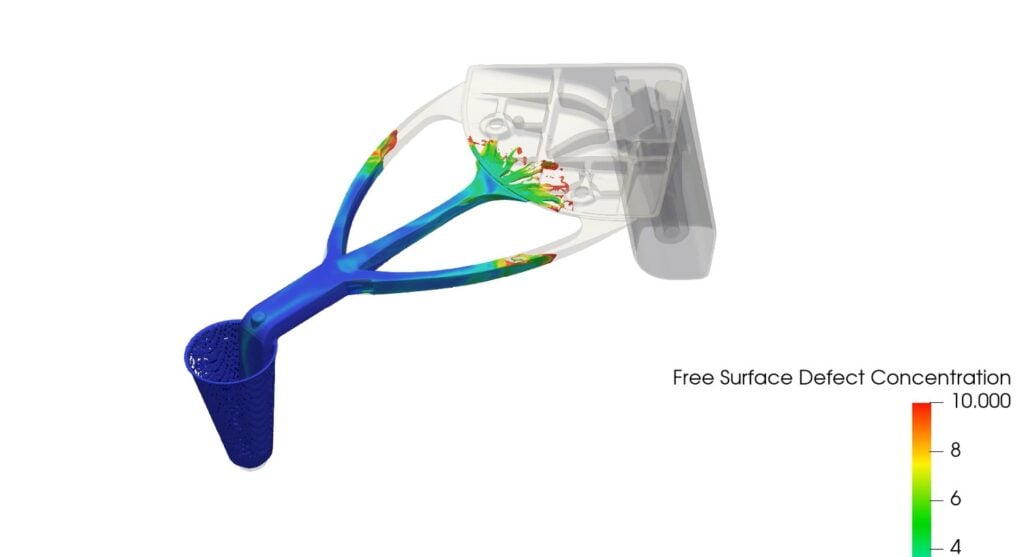

After the initial print review, Mold Flow can sometimes be helpful to address concerns around manufacturability. Mold flow will help our engineers assess areas at risk for air entrapment. Air will always be entrapped in a high-pressure zinc die cast product. However, we can work with you to control where the air is getting entrapped to maximize the performance needs of the product.

Our team can also identify areas of concern related to how the part will heat up and cool down. Although castings form a solid shape immediately after getting injected into the mold, they will remain hot for quite a while. As the castings cool down, they will also shrink into their final size. Some parts are at risk to warp or curl depending on how the heat is managed in the die and as the part cools.

Some customers want prototypes for fit-testing, other customers want to understand how the zinc casting will perform under impact stress or under load. Depending on your needs, there are multiple ways to generate prototype parts. Although Deco does not have many of these capabilities, we always want to support our customers with the best advice we can provide. Here are a few common ways to produce a prototype.

This is typically our top recommendation for customers looking to make prototypes of a die cast part without a tooling investment. This prototyping approach machines parts out of zinc barstock and provides for quick prototypes. This typically gives a good indication of the mechanical potential of the product design. It is typically possible to purchase special metal that has been produced to have similar properties to cast zinc of whatever alloy you need.

Unfortunately, the surface characteristics of the part are compromised as the material is machined. Normally, zinc castings form a “skin” of dense material at the outside surface of the part, allowing for a great appearance and the ability to easily plate or powder coat the casting. In this case, a machined part will not have a representative finish.

This is typically expensive per piece but comes with the advantage of no-tooling.

There are a variety of methods to cast parts with little investment in tooling, including sand casting, spin casting, and investment casting. Generally, speaking, we tend to suggest sand or spin casting, especially when working with smaller parts. These casting methods allow for complex geometries, but tend to perform much worse for recreating tight tolerances and potentially compromised surface quality.

Prototype tooling is less expensive than production tooling with this method, but more expensive than other prototyping methods. Complex geometries are possible, but the quality is compromised and the quantity of parts to be produced is lowered. This method is expensive but can provide a better surface finish than other prototyping methods.

3D printing has evolved and redefined many industries. A 3D printed part is inexpensive and readily available. It can be used to physically illustrate how the part would look, and used to test special packaging needs, but will not allow for any performance assessment.

The best way to understand how an aluminum or zinc casting will perform, both internally and externally, is to invest in tooling and have production die castings run on a real die-cast machine. There are a few ways to reduce the cost of this type of prototyping exercise by reducing the overall tooling investment.

A large number of our customers very carefully validate their first product designs with a real production tool. For parts that are successful, this ends up being the best total cost to the customer, with no additional lead-time to launch the production process as the tool is ready to go.

One thing to keep in mind is “tool safe” changes: it is relatively easy to remove additional metal from the tool (ie adding material to the part). However, once steel has been removed, the process to add material back usually involves welding material on and re-machining that area. While changes of this nature can be done, it is much better for the longevity of the tool to remove additional tool steel to form a functional part.

One way to reduce tooling cost is to build a tool with a single cavity. This can either be done by producing a smaller tool to validate the product, developing an insert to make the part in a larger tool holder, or by using the correct tool size for the final application, but only machining out the first cavity. By machining out only the first cavity, tooling can be validated before the entire tool is produced.

We generally do not recommend tooling an item in a small single-cavity tool if the ultimate volume warrants a larger tool with more cavities. However, this can be a good solution for customers with a higher tolerance for higher piece prices while they prove out the concept and their product market.

Some customers have requested a “soft” tool prototype. This generally means it is a production tool made with a less expensive version of tool steel. The material is less hard, meaning the tool will have a shorter life. We generally discourage customers from entertaining this prototype strategy, as it is not that much cheaper than hardened tool steel, and invariable means the customer will be purchasing another tool soon.

Regardless of what method of prototype you pursue, a good design review between your Engineering team and ours is the most important step of any product development.

If you need a prototype without tooling, we generally recommend machining a shape out of Zamak material that has been cast to capture the correct physical properties.

For a real understanding of the product, investing in some form of tooling will give you the most accurate representation of the product performance and provide you an asset you can use for production.